Ease of Handling and Installation: Flexible rubber extension cables are inherently easier to manage during installation and everyday use. Their pliability allows them to be routed around obstacles, threaded through tight spaces, and bent into required shapes without causing damage to the internal conductors. This feature is particularly valuable in dynamic work environments where cables need to be frequently repositioned or temporarily installed, such as in construction sites, stage setups for events, or temporary power distribution scenarios.

Durability: The inherent flexibility of rubber materials provides excellent resistance to mechanical stress. Rubber extension cables can endure repeated bending, twisting, and coiling without the risk of cracking or breaking, which commonly occurs in less flexible materials like PVC. This resilience extends the service life of the cable, making it a reliable choice for environments where cables are subjected to continuous movement or mechanical wear, such as in factories with moving machinery or outdoor applications where cables might be run over by vehicles.

Resistance to Environmental Factors: Rubber extension cables maintain their flexibility across a wide temperature range, which prevents them from becoming brittle in cold weather or excessively soft in high temperatures. This adaptability is crucial for outdoor applications, including construction sites in cold climates and industrial environments with high heat exposure. Rubber is highly resistant to moisture, oils, chemicals, and UV radiation, making these cables suitable for harsh environments such as chemical plants, marine settings, and outdoor installations where exposure to the elements is inevitable.

Safety: Flexible rubber extension cables are less prone to damage from bending or kinking, which reduces the likelihood of internal conductor breaks or insulation cracks. Such damages can lead to electrical shorts, sparking, or even fires. By maintaining structural integrity, these cables enhance overall safety in environments where reliable electrical performance is critical, such as hospitals, data centers, and industrial facilities.

Adaptability to Different Surfaces: The flexibility of rubber extension cables allows them to conform to uneven or irregular surfaces, making them suitable for a variety of terrains and surfaces found in diverse environments. For instance, on construction sites, cables can be laid over rocky or uneven ground without the risk of damage. In indoor settings, they can be routed discreetly along walls, ceilings, or floors, minimizing trip hazards and maintaining a neat appearance.

Vibration and Impact Resistance: In environments where cables are exposed to vibrations from heavy machinery or frequent impacts, the flexibility of rubber cables allows them to absorb and dissipate energy more effectively than rigid cables. This resistance to mechanical stress helps prevent damage to the cable's internal structure, ensuring continuous and reliable electrical performance in high-vibration environments such as manufacturing plants, transportation hubs, and construction sites.

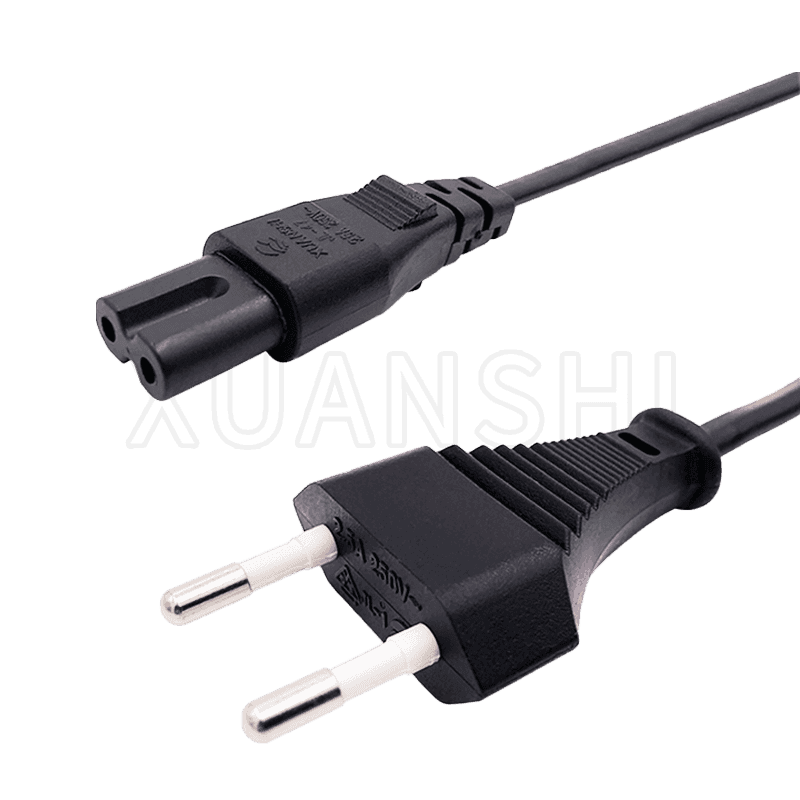

European 2 pin plug power cord with C7 Connector JL-1,JL-47