Rubber extension cables designed for outdoor use typically incorporate features that address concerns related to UV radiation exposure. UV radiation from the sun can degrade the rubber material over time, affecting the cable's performance and lifespan. Here are ways in which these cables mitigate UV exposure concerns:

Polymer Composition for UV Resistance: The selection of polymers for the cable's outer jacket is based on a meticulous analysis of their chemical composition. These polymers are not only UV-resistant but are chosen for their specific molecular structures that exhibit a high degree of resilience against the photochemical reactions induced by UV radiation. This ensures that the cable remains pliable and maintains its structural integrity even when exposed to intense sunlight for prolonged periods.

Advanced Weatherproofing Techniques: The weatherproofing process involves the application of advanced techniques such as extrusion or injection molding with precision. This meticulous process creates a seamless and robust protective layer, enveloping the cable. Specialized weatherproofing agents are incorporated to form a shield that not only repels UV rays but also guards against the corrosive effects of rain, snow, and other environmental factors. This multi-layered defense fortifies the cable against a spectrum of challenges posed by outdoor conditions.

UV Stabilizer Synergies: The incorporation of UV stabilizers involves a nuanced approach, where a synergistic blend of stabilizing agents is strategically mixed into the rubber compound. This synergy enhances the cable's resistance to UV-induced degradation, creating a formidable defense mechanism. The careful balance of these stabilizers ensures that the cable not only withstands direct UV exposure but also maintains its electrical and mechanical properties over an extended service life.

Testing Protocols: The testing protocols extend beyond conventional assessments, encompassing a battery of tests designed to simulate real-world UV exposure scenarios. Accelerated aging chambers subject the cable to intense UV radiation, replicating the harsh conditions it might encounter in outdoor environments. These tests not only evaluate the cable's resistance to UV but also scrutinize its overall performance, ensuring that it not only meets but exceeds industry standards for reliability and longevity.

Thermal Dynamics of Color Selection: The color selection process is not arbitrary; it delves into the intricate dynamics of thermal management. Lighter colors are chosen not only for their reflective properties but also for their ability to minimize heat absorption. This meticulous consideration mitigates the risk of thermal damage, ensuring that the cable remains operationally sound even under the intense heat generated by prolonged exposure to direct sunlight.

Holistic Outdoor Suitability Specifications: The product specifications encapsulate a holistic view of the cable's outdoor suitability. They delve into nuanced details about its performance under diverse environmental stresses, including UV radiation. These specifications serve as a user-centric resource, offering a detailed roadmap for deploying the cable in various outdoor applications. Compliance with industry standards is not just a checkbox; it signifies a commitment to providing users with a solution that excels in the complex challenges posed by outdoor environments.

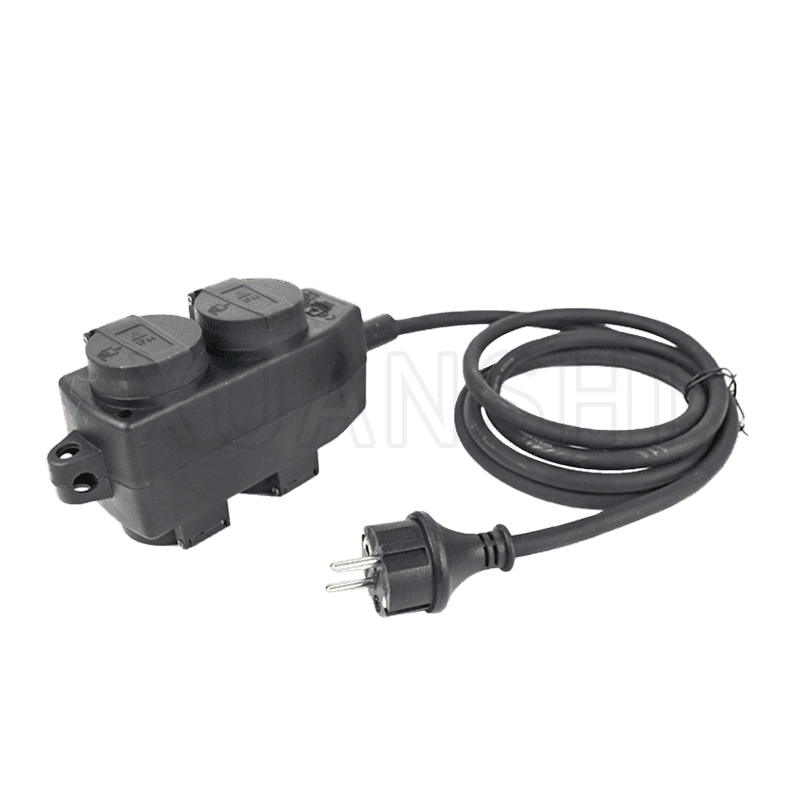

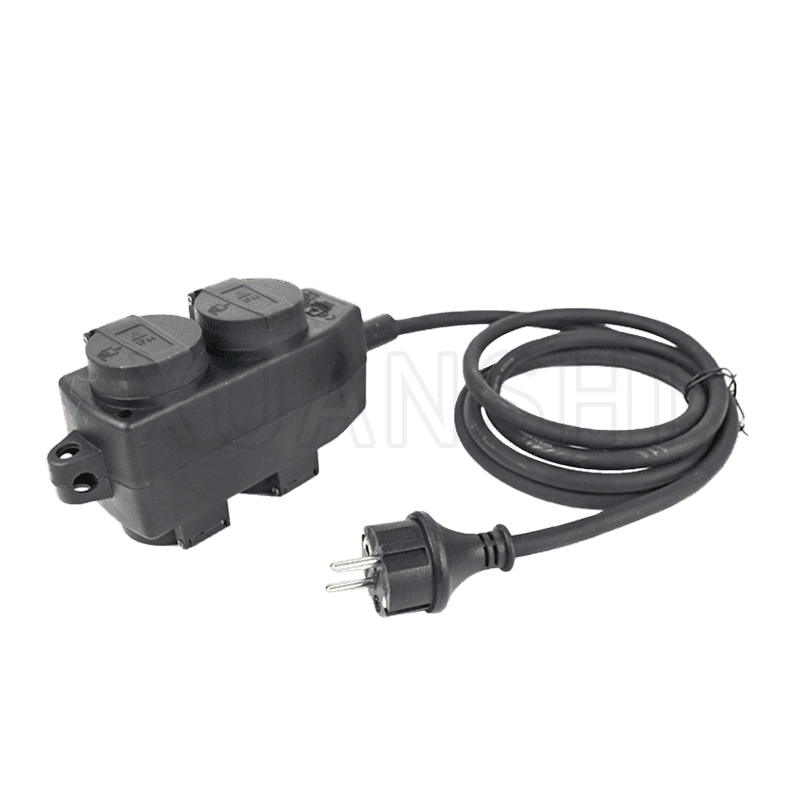

European 4 way IP44 waterproof distributor socket JL-3F,XS-XBD4A