Rubber insulation is renowned for its superior flexibility, which is a critical factor for applications requiring frequent movement or bending. This flexibility is achieved through the intrinsic properties of rubber polymers, which maintain pliability and resilience even under repetitive stress. As a result, rubber-insulated cables are less prone to kinking, cracking, or breaking compared to cables with less flexible materials. The ability to withstand continuous bending and twisting helps ensure that the cable can be used in dynamic environments, such as construction sites or manufacturing facilities, without compromising its performance or structural integrity. This durability translates into a longer service life and reduced maintenance or replacement costs.

Rubber’s abrasion resistance is a key feature for cables subjected to physical wear and tear. The outer layer of rubber acts as a tough shield against abrasive forces, which could otherwise erode or damage the cable’s surface. This resistance is particularly important in environments where the cable is in constant contact with rough surfaces or subjected to frequent movement, such as in industrial machinery or outdoor settings. By protecting the underlying conductors from mechanical damage, rubber insulation helps maintain the cable’s performance and safety over time, ensuring reliable operation even in high-friction scenarios.

Rubber insulation provides exceptional protection against moisture and a wide range of chemicals, making it highly suitable for challenging environments. The material’s hydrophobic properties prevent water from penetrating the insulation, which is crucial for avoiding electrical short circuits and degradation of the cable’s performance. Rubber’s resistance to chemicals such as oils, solvents, and acids means that the cable can withstand exposure to harsh substances without deteriorating. This resistance helps maintain the cable’s mechanical and electrical properties, ensuring it remains functional and safe in environments like industrial plants, laboratories, and outdoor settings.

The electrical insulating properties of rubber are critical for ensuring safe and reliable operation. Rubber’s high dielectric strength allows it to withstand substantial electrical voltages without breaking down or allowing current leakage. This property is essential for preventing short circuits and reducing the risk of electrical shocks. The insulation effectively isolates the conductive wires within the cable, maintaining electrical integrity and safety. The uniformity and consistency of rubber insulation contribute to a stable and reliable performance, even in high-voltage applications.

Rubber insulation exhibits excellent thermal stability, which is crucial for cables operating in varying temperature conditions. Rubber’s ability to remain flexible and retain its insulating properties across a broad temperature range—from extremely low to high temperatures—ensures that the cable performs reliably in diverse environments. This temperature resistance helps prevent issues such as insulation degradation, cracking, or loss of flexibility, which can occur in less temperature-stable materials. By maintaining performance in both freezing cold and intense heat, rubber-insulated cables are versatile and adaptable to a wide range of operational conditions.

Rubber’s inherent shock-absorbing qualities provide significant impact resistance, which is vital for protecting the cable from physical damage. The material’s elasticity allows it to absorb and dissipate impact forces, reducing the risk of internal conductor damage and insulation failure. This impact resistance is particularly important in applications where cables are subject to accidental drops, collisions, or rough handling. The ability of rubber to cushion and protect the cable ensures continued functionality and safety, even under challenging physical conditions.

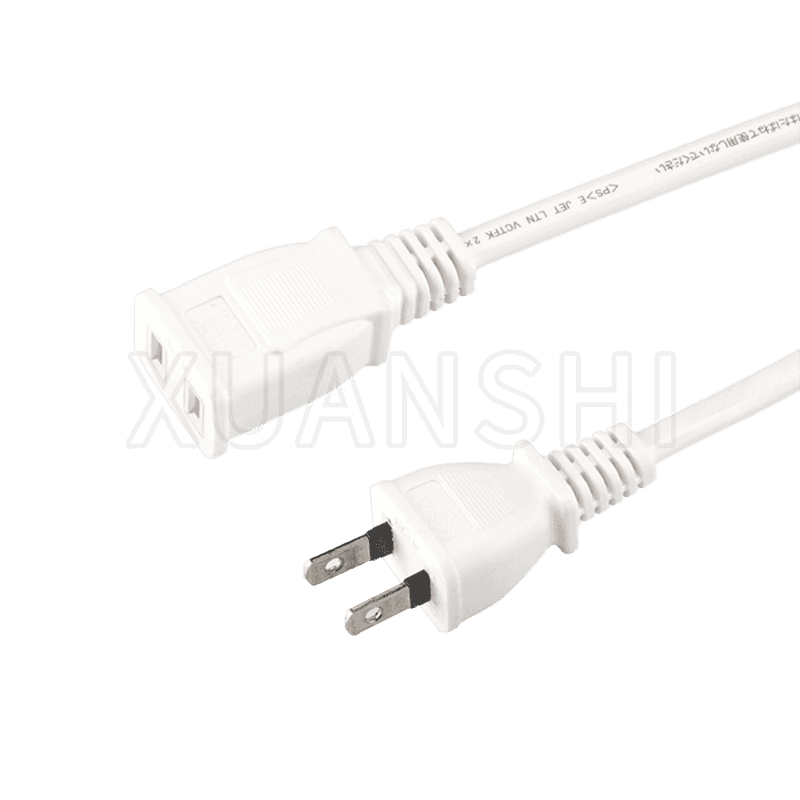

Japan 2 pin plug extension cord