Managing heat dissipation in a socket power extension cord, especially when multiple devices are plugged in, is crucial for safety and longevity. Here's how it can be managed:

High-Quality Materials: Utilizing premium-grade materials in the construction of socket power extension cords is paramount to ensuring positive heat dissipation and overall safety. High-quality extension cords are characterized by heavy-duty copper wiring, renowned for its exceptional conductivity and resistance to heat generation. The copper conductors are typically constructed with high purity levels to minimize resistance and subsequent heat buildup during operation. The insulation surrounding the conductors is crafted from flame-retardant materials, such as polyvinyl chloride (PVC) or thermoplastic elastomers (TPE), engineered to withstand elevated temperatures without compromising structural integrity or posing fire hazards.

Adequate Gauge: The gauge, or thickness, of the wires within a socket power extension cord directly influences its capacity to manage heat dissipation effectively. Thicker gauge wires exhibit lower electrical resistance, facilitating the smooth flow of current with minimal impedance. This characteristic is particularly advantageous when powering multiple devices simultaneously, as it minimizes resistive losses and consequent heat generation. Extension cords with ample wire gauges, typically measured in American Wire Gauge (AWG) units, offer enhanced conductivity and reduced voltage drop across the cord's length. By selecting an appropriate wire gauge commensurate with the intended application and load requirements, users can mitigate the risk of overheating while optimizing electrical performance and efficiency.

Built-in Thermal Protection: Advanced socket power extension cords often incorporate sophisticated thermal protection mechanisms designed to safeguard against overheating and mitigate associated risks. These integrated safety features employ temperature-sensitive sensors or thermistors strategically positioned within the cord's structure to monitor operating conditions in real time. Upon detecting abnormal temperature fluctuations indicative of potential overheating, the thermal protection system promptly activates, automatically interrupting the power supply to prevent further escalation. Some extension cords may feature resettable circuit breakers or thermal fuses that trip in response to excessive heat, effectively isolating the affected circuit and mitigating fire hazards.

Spacing of Outlets: Optimal outlet spacing is a critical design consideration in socket power extension cords, profoundly impacting heat dissipation and usability. Extension cords featuring well-spaced outlets facilitate efficient airflow and heat dispersion between connected devices, thereby minimizing the risk of localized heat buildup and thermal stress. The strategic arrangement of outlets ensures ample clearance between plugs, accommodating various plug sizes and configurations without impeding airflow. Extension cords equipped with rotating or swiveling outlets offer greater flexibility in positioning connected devices, further optimizing airflow and heat dissipation.

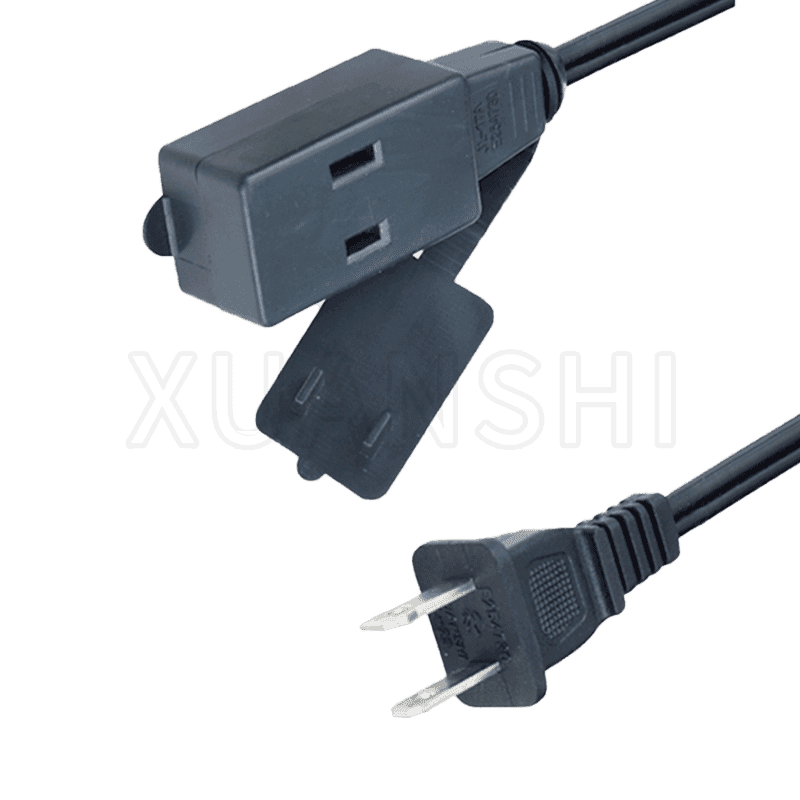

American Standard Socket Extension Cord JL-23,JL-17A