The key differences between a 3 Pin Plug Power Cord for residential use and one designed for industrial applications primarily revolve around factors such as durability, safety, and environmental considerations. Here are some distinctions:

Durability and Build Quality:

Residential: Residential power cords are meticulously engineered with a primary focus on day-to-day use. The construction emphasizes compatibility with standard household appliances and electronic devices, featuring wires with a lower gauge to adeptly manage the moderate loads typically associated with common residential equipment.

Industrial: Conversely, industrial power cords undergo a robust design process prioritizing durability. These cords boast heavier gauge wires, a testament to their capacity to handle higher loads intrinsic to industrial machinery. The overall build is rugged, strategically fortified to withstand the incessant wear and tear incurred through continuous operation in demanding industrial environments.

Voltage and Current Ratings:

Residential: Power cords intended for residential use are purposefully crafted to meet the prevalent voltage and current requirements of household electrical systems, generally oscillating between 120V or 240V depending on regional standards.

Industrial: Industrial power cords are engineered with the foresight to accommodate higher voltages and currents typical in industrial settings. This ensures seamless compatibility with the power demands of heavy-duty machinery and equipment integral to industrial operations.

Environmental Resistance:

Residential: Residential power cords, while not explicitly designed for resistance to environmental factors or chemical exposure, are tailored for controlled indoor environments, where such considerations are not paramount.

Industrial: In stark contrast, industrial power cords are fortified with advanced insulation and coatings. This strategic fortification serves as a line of defense, enabling these cords to resist the corrosive impact of chemicals, the degrading influence of oils, and the extremes of temperature fluctuations prevalent in challenging industrial settings.

Flexibility and Strain Relief:

Residential: In the residential realm, power cords prioritize flexibility to cater to the dynamic nature of household devices. While adequate strain relief mechanisms are present, they are calibrated to meet the typical demands of household use.

Industrial: Industrial power cords strike a delicate balance between flexibility and stiffness. Their design incorporates robust strain relief mechanisms, a critical feature essential for preventing damage at connection points. This consideration is especially vital in industrial environments where these cords are subjected to frequent movement and potential rough handling.

Safety Features:

Residential: Safety features in residential power cords are tailored to meet fundamental requirements, often centering around grounding mechanisms aimed at averting electrical shocks in everyday household scenarios.

Industrial: Industrial power cords raise the safety bar significantly, integrating advanced features such as supplementary grounding, enhanced insulation, and sophisticated shielding. These features are imperative in meeting the stringent safety standards mandated by industrial environments, where the risk of electrical hazards is inherently elevated.

Length and Installation:

Residential: Power cords for residential use are conventionally available in standardized lengths, catering to the needs of typical household applications. Their design is inherently user-friendly, facilitating do-it-yourself installations commonly associated with residential setups.

Industrial: Industrial power cords offer versatility in terms of length and often demand customized configurations tailored to specific industrial applications. Due to the intricacies of industrial safety standards and the diverse requirements of different machinery and equipment, professional installation is highly recommended to ensure compliance and optimal performance.

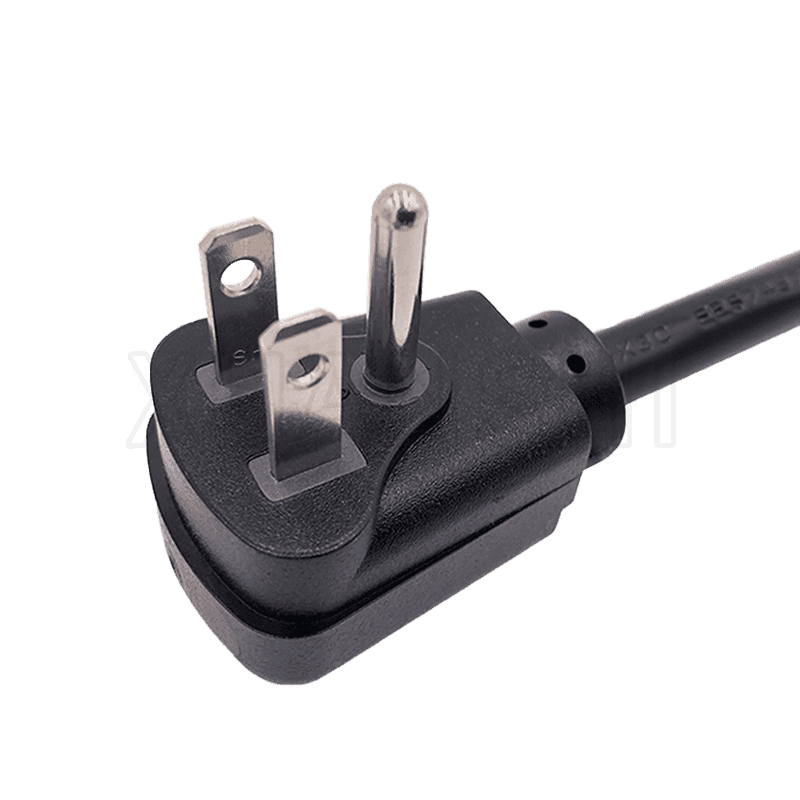

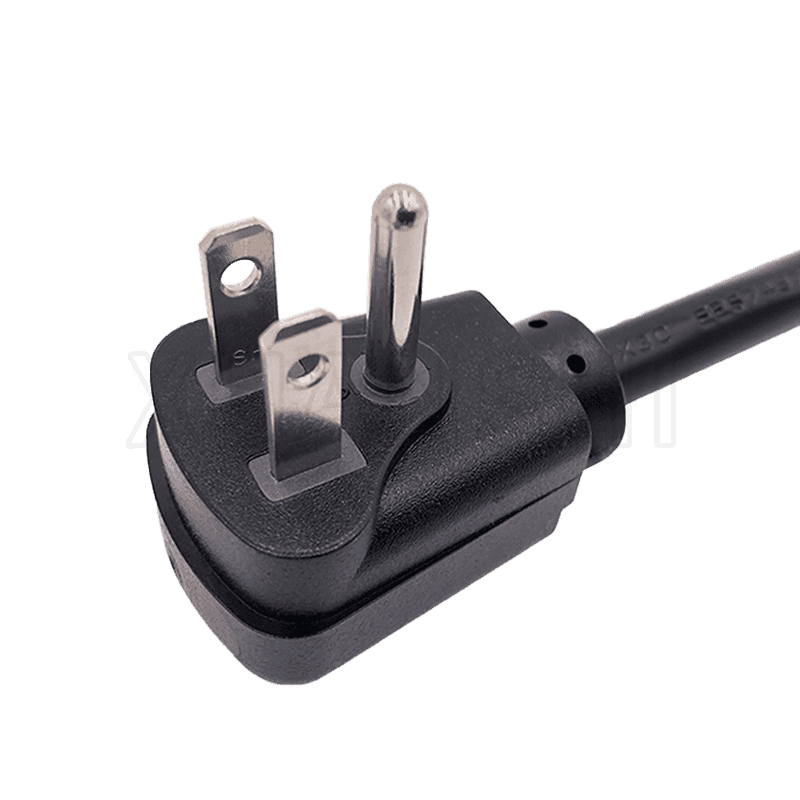

America 3 pin NEMA 5-15P plug power cord JL-16