When choosing a 3 Pin Plug Power Cord for electronic devices, several key factors should be considered to ensure safety, compatibility, and optimal performance. Here are the key factors to keep in mind:

Voltage and Current Ratings: Conduct an in-depth analysis of your electronic device's power specifications, considering both steady-state and transient conditions. Explore voltage fluctuations and their potential impact on the device's performance. Delve into the nuances of current draw during startup or peak usage to ensure that the chosen 3 Pin Plug Power Cord can handle dynamic power demands without compromising stability.

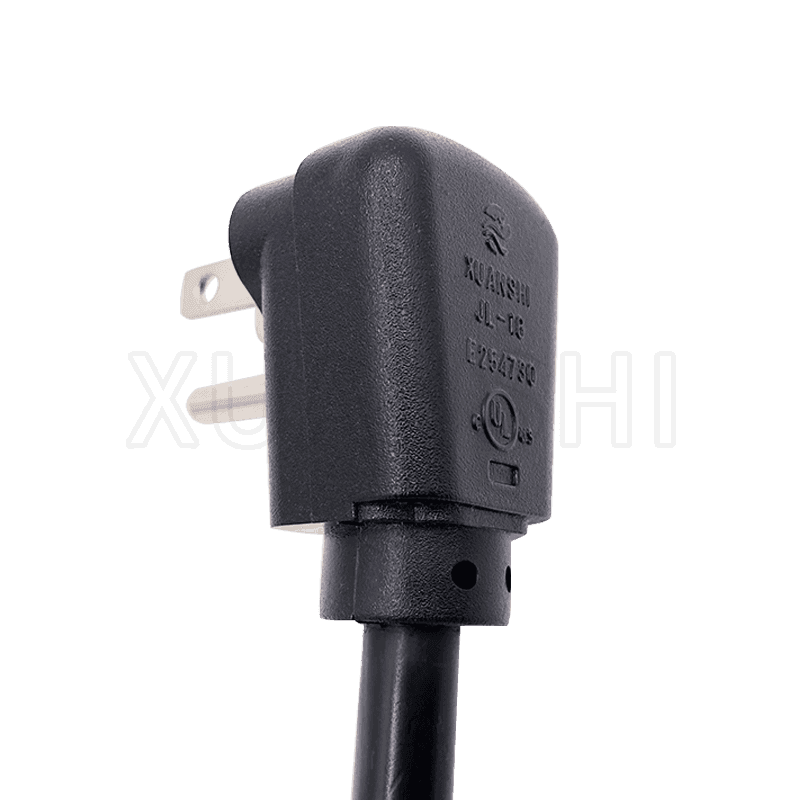

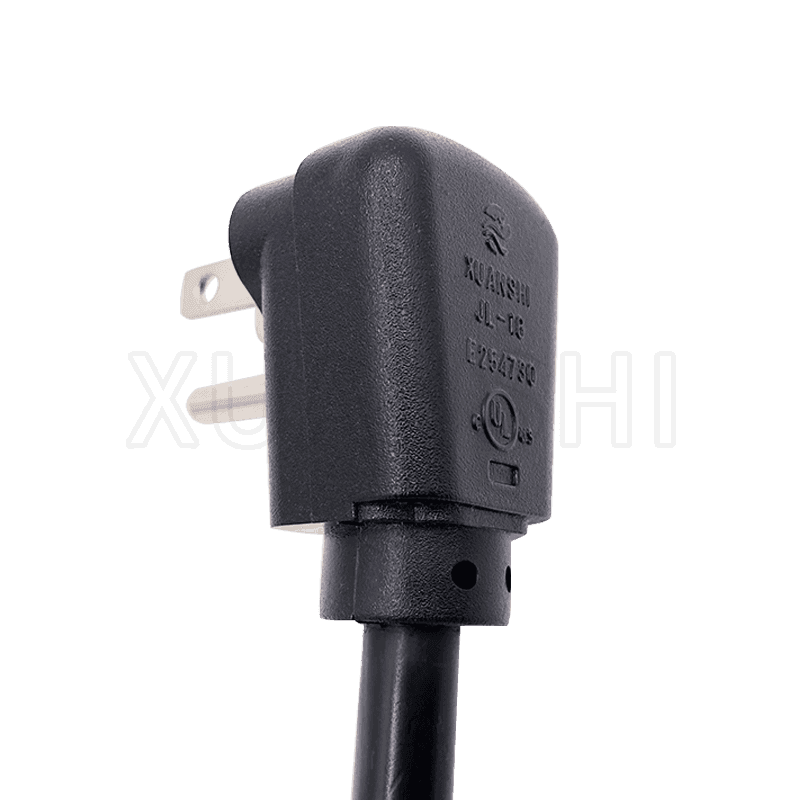

Plug Type: Immerse yourself in the intricate details of plug design, considering not only regional variations but also the ergonomic aspects of plug insertion and removal. Research the mechanical tolerances of plug pins, evaluating factors such as contact pressure and durability. Explore plug materials to understand their resistance to wear and corrosion over extended usage.

Cord Length: Undertake a comprehensive spatial analysis, factoring in not just the physical distance but also the impedance characteristics of the power cord. Investigate the impact of inductance and capacitance over longer lengths, considering power factor correction and signal integrity. Conduct simulations or calculations to optimize cord length for minimal power loss and efficient energy transfer.

Compatibility: Conduct a thorough analysis of communication protocols, exploring potential signal interference or crosstalk between power and data lines. Investigate the power factor correction requirements of the device and assess how the power cord contributes to maintaining power quality. Simulate scenarios where multiple devices share a common power source to ensure compatibility and stability in complex setups.

Materials and Build Quality: Engage in a detailed examination of material properties, conducting tests for thermal conductivity, flame resistance, and mechanical strength. Explore the impact of connector materials on contact resistance and corrosion over extended usage. Utilize advanced testing equipment to assess the cord's performance under mechanical stress, ensuring a high level of durability and longevity.

Environmental Considerations: Undertake a comprehensive environmental impact assessment, considering not only resistance to temperature and humidity but also the cord's ecological footprint. Explore sustainable material options and their impact on the cord's performance. Conduct accelerated aging tests to simulate long-term exposure to environmental factors and ensure the cord's resilience over its entire lifecycle.

Flexibility: Employ advanced materials engineering to optimize the cord's flexibility characteristics. Utilize stress-strain analysis to model the cord's behavior under repeated bending or twisting. Consider the impact of temperature variations on the cord's flexibility and conduct real-world simulations to validate its performance in diverse usage scenarios.

Ease of Storage: Employ ergonomic design principles to optimize storage features, considering not only convenience but also the impact on the cord's structural integrity. Utilize advanced materials for retractable mechanisms or storage solutions to ensure longevity and reliability. Conduct user studies to validate the effectiveness of storage features in real-world scenarios.

America 3 pin NEMA 5-15P plug power cord JL-16