Rubber extension cables are typically designed with different temperature ratings to make them suitable for various environments and applications. The two primary temperature ratings you'll often encounter are the insulation temperature rating and the jacket temperature rating. These ratings play a crucial role in determining where and how the cable can be used:

1.Insulation Temperature Rating: This rating indicates the maximum temperature at which the cable's insulation material can safely operate without degrading or losing its insulating properties. Common insulation temperature ratings for rubber extension cables include 60°C, 75°C, and 90°C.

60°C: Rubber extension cables with a 60°C insulation temperature rating are generally intended for standard indoor applications. They are well-suited for environments where temperature extremes are not a concern. Examples include office settings, workshops, or residential use.

75°C: Cables rated for 75°C insulation are versatile and commonly used for outdoor applications. They offer improved resistance to moderate heat and can endure temperature fluctuations. These cables are suitable for construction sites, outdoor events, or general outdoor use.

90°C: Cables with a 90°C insulation rating are designed for more demanding industrial applications. They are capable of withstanding high temperatures and are ideal for use in manufacturing plants, foundries, or any environment where heat is a constant factor.

2.Jacket Temperature Rating:The jacket of the cable is the outer protective layer, and its temperature rating indicates the maximum temperature the cable can be exposed to externally without the jacket deteriorating. Common jacket temperature ratings are 75°C and 90°C.

75°C: Rubber extension cables with a 75°C jacket temperature rating are suitable for a wide range of outdoor applications. This rating ensures that the cable's outer protective layer can endure exposure to sunlight, rain, and temperature variations without degrading. These cables are often used in construction, landscaping, or outdoor entertainment setups.

90°C: A jacket with a 90°C temperature rating offers enhanced protection against extreme conditions. It is commonly chosen for industrial settings where the cable may be exposed to high temperatures, corrosive chemicals, or abrasive substances. This rating ensures the cable can maintain its structural integrity and protective qualities in harsh environments.

The temperature ratings are essential because they ensure the cable's safe and reliable performance in specific conditions. For instance:

In hot climates or applications with high temperatures, using a rubber extension cable with a higher temperature rating is crucial to prevent insulation or jacket damage.

When exposed to cold temperatures, cables with lower temperature ratings may become less flexible and more susceptible to cracking or breaking.

Outdoor applications require cables with jacket materials that can withstand UV exposure, moisture, and temperature fluctuations.

In industrial settings, where cables might be exposed to chemicals or abrasive conditions, choosing a cable with a suitable temperature rating ensures longevity.

Understanding the temperature ratings of rubber extension cables is essential for selecting the right cable for your specific environment and ensuring safety and performance.

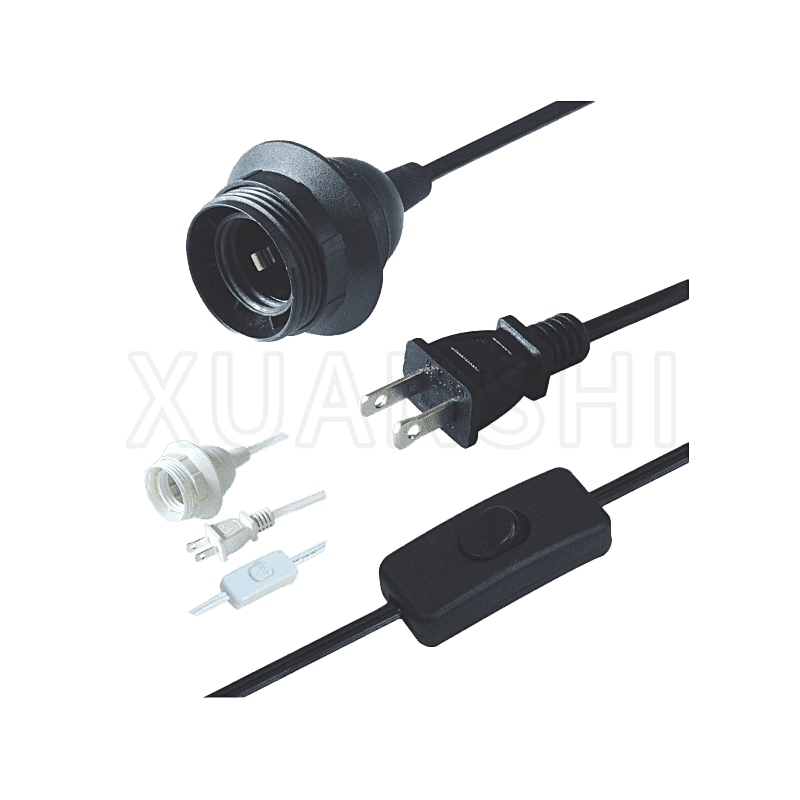

Model: JL-17/303/E26

Wiring: SVT 18AWG/2C

Exterior Color: black/white

Packaging Details: paper box